Exploring Schneider’s Smart Contactors

In the rapidly evolving landscape of industrial automation and control, staying ahead of technological advancements is essential for maintaining operational efficiency and competitiveness. Schneider Electric, a global leader in energy management and automation, offers innovative solutions to meet these demands. Among their cutting-edge offerings are smart contactors, which bring a host of advanced features designed to enhance control, monitoring, and maintenance in industrial settings. This blog delves into the innovative features of Schneider’s smart contactors, such as remote monitoring, predictive maintenance capabilities, and integration with IoT systems, and discusses how these advancements are reshaping industrial control and optimising operational efficiency in modern manufacturing environments.

Understanding Smart Contactors

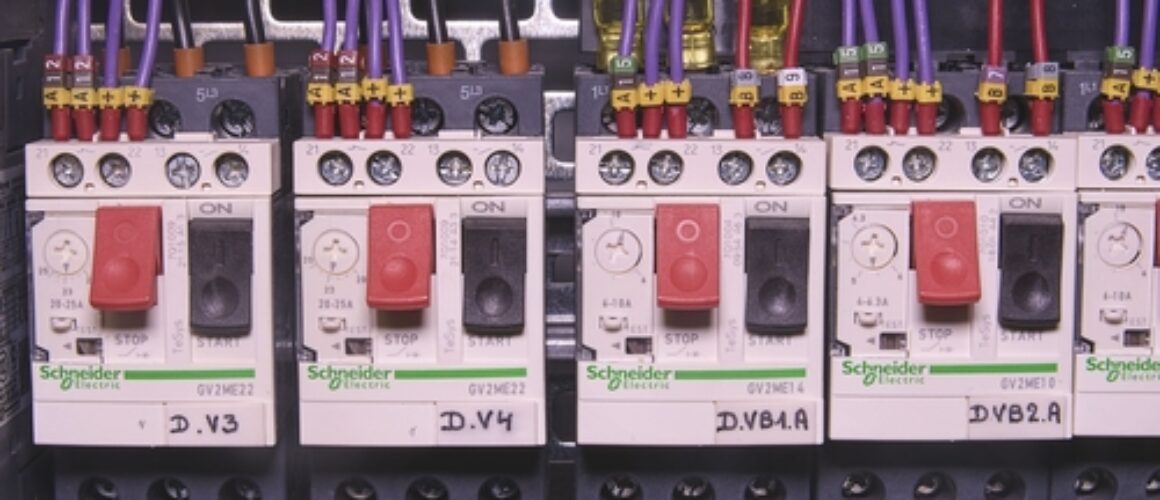

A contactor is an electrically controlled switch used for switching an electrical power circuit. Traditional contactors have been essential components in industrial control systems, providing reliable switching for motors, lighting, heating, and other electrical loads. However, Schneider’s smart contactors take this a step further by incorporating advanced features that leverage digital technology and the Internet of Things (IoT).

Key Features of Schneider’s Smart Contactors

1. Remote Monitoring

One of the standout features of Schneider’s smart contactors is their remote monitoring capability. Through integrated communication modules, these contactors can be monitored in real-time from remote locations. This feature offers several significant benefits:

Real-Time Data Access: Operators can access real-time data on the status and performance of contactors, including voltage, current, and power consumption. This visibility allows for timely interventions and adjustments.

Enhanced Visibility: Remote monitoring provides a comprehensive overview of the entire control system, enabling better decision-making and quicker response times to any anomalies or issues.

Reduced Downtime: By monitoring the contactors remotely, potential issues can be identified and addressed before they lead to equipment failure or system downtime, ensuring continuous operation.

2. Predictive Maintenance

Predictive maintenance is a game-changer in industrial environments, allowing for maintenance activities to be planned based on the actual condition of equipment rather than on a fixed schedule. Schneider’s smart contactors are equipped with predictive maintenance capabilities that offer the following advantages:

Condition-Based Monitoring: Smart contactors continuously monitor their own performance and the condition of connected equipment. This data can be used to predict when maintenance is required, reducing the likelihood of unexpected failures.

Cost Savings: By preventing unexpected breakdowns and minimising unnecessary maintenance, predictive maintenance can lead to significant cost savings. Resources are only used when needed, extending the lifespan of equipment and reducing operational costs.

Increased Reliability: Predictive maintenance helps ensure that systems remain in optimal working condition, enhancing overall reliability and performance.

3. Integration with IoT Systems

The integration of smart contactors with IoT systems represents a significant advancement in industrial control. Schneider’s smart contactors are designed to communicate with IoT platforms, enabling seamless integration into broader industrial automation systems. Key benefits include:

Centralised Control: IoT integration allows for centralised control and monitoring of all connected devices and systems, facilitating more efficient management and coordination.

Data Analytics: IoT platforms can collect and analyse data from smart contactors, providing valuable insights into system performance, energy usage, and operational efficiency. These insights can inform decision-making and drive continuous improvement.

Scalability: As industrial operations expand, the ability to integrate new devices and systems into existing IoT platforms ensures scalability and future-proofing of the control system.

Reshaping Industrial Control

The advanced features of Schneider’s smart contactors are reshaping industrial control in several key ways:

1. Optimising Operational Efficiency

By providing real-time monitoring, predictive maintenance, and IoT integration, smart contactors enable more efficient and effective control of industrial systems. Operators can optimise energy use, reduce waste, and ensure that equipment operates at peak performance. This optimisation translates to higher productivity and lower operational costs.

2. Enhancing Safety and Reliability

Safety is a paramount concern in industrial environments. Smart contactors enhance safety by providing real-time alerts and automatic shutdowns in case of faults or abnormal conditions. Predictive maintenance further contributes to safety by reducing the risk of unexpected equipment failures that could lead to hazardous situations.

3. Facilitating Remote Operations

The ability to monitor and control systems remotely is particularly valuable in today’s increasingly interconnected world. Remote operations allow for greater flexibility, enabling operators to manage and troubleshoot systems from anywhere, at any time. This capability is especially beneficial in large-scale or geographically dispersed operations.

4. Driving Innovation

The integration of smart contactors with IoT systems fosters a culture of innovation. By leveraging data analytics and digital technologies, industrial operations can continuously improve and adapt to changing conditions. This innovation is crucial for staying competitive in a rapidly evolving market.

Conclusion

Schneider’s smart contactors represent a significant advancement in industrial control technology. Their innovative features, such as remote monitoring, predictive maintenance capabilities, and IoT integration, are transforming the way industrial systems are managed and operated. These advancements not only optimise operational efficiency and enhance safety but also pave the way for future innovations in industrial automation.

To explore Schneider’s range of smart contactors and discover how they can benefit your industrial operations, visit Electrical Discounted Supplies. Equip your systems with the latest in smart contactor technology to achieve greater efficiency, reliability, and control in your manufacturing environment.